Toyota's New Paint Atomizer – 95% Coating Efficiency!

Color has always been critical in the automotive industry and plays a significant role when choosing a new car! We all want a color that is easy on the eyes brings a sense of pride and ownership, and elicits emotions of excitement!

Toyota's Breakthrough In Paint Technology!

Toyota's newly developed airless painter is one of a kind and the first to achieve 95% coating efficiency. Coating efficiency refers to the amount of paint sprayed versus the amount that adheres to the body. Previously, this technology was 60-70% efficient, but with Toyota's breakthrough, the paint world is bound to change!

The airless paint atomizer in Toyota's Group is expected to reduce CO2 emissions by approximately 7%. Additionally, the collective device situated at the bottom of the paint booth can be made more compact for the future!

This breakthrough follows Toyota's Plant Zero CO2 emissions Challenge, which is a part of their 2050 plan as announced in 2015. The airless paint atomizer has been deployed at the Takaoka and Tsutsumi Plants already, and they have planned a gradual deployment at their other plants as well. Considerations regarding licensing this technology to other companies are also underway!

What was the conventional working principle?

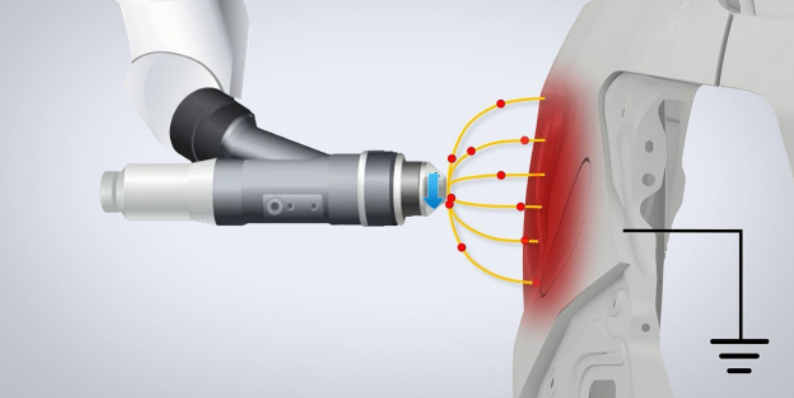

The conventional working principle of the air paint atomizer was the aerodynamic force, which is why the paint particles would scatter and ricochet off the vehicle body resulting in only 70% efficiency at best. Compared to the new paint atomizer technology, the airless paint atomizer uses electricity to spray the paint. Per the principle of electrostatic atomization, statically charged particles coat paint in a way that they gravitate towards the vehicle body - hence, 95% efficiency!

The electrostatic atomization and paint technologies reduce the number of atomized particles by a considerable degree, and that is how an increased coating efficiency is achieved.

What is the working principle of the paint atomizer?

The tip of the paint atomizer consists of a rotating cylindrical head which optimizes the amount of paint sprayed. This technology is also used in beauty treatment devices and other instruments where a fine spray of liquid is crucial. Taking inspiration from relevant devices, the tip of the paint sprayer is cylindrical, and 600 unique grooves are inserted into the tip. The tip is then rotated to create a centrifugal force which induces the paint to flow into the grooves and atomize through static electricity. This is how the world's first atomizer has been created for 95% efficiency on vehicle bodies!

What are the benefits of this technology?

The primary benefit of this device is the highly accurate control that ensures close-range painting. The unevenness of the vehicle body causes the distance between the cylindrical head and vehicle body to fluctuate, resulting in an unstable current. The airless paint atomizer has been developed to monitor the variations in current and control the voltage to maintain approximately 10 cm distance. It is how electrostatic atomization and electrostatic painting under a fixed are made possible. It also prevents variation in the size of the paint particles, which results in a higher paint quality!